Alberta Landowners Guide, Oil Batteries and Gas Compressor Plants

3rd edition | |

| Authors: | Duncan Kenyon, Nikki Way, Andrew Read, Barend Dronkers, Benjamin Israel, Binnu Jeyakumar, Nina Lothian |

|---|---|

| Publisher: | Pembina Institute |

| Publish Date: | October 2016 |

| PDF Download: | [Landowners' Guide] [Landowners' Primer] |

| Initiation Phase | |

| Exploration Phase | |

| Development Phase | |

| Pipelines and Other Infrastructure Pipelines and Emergency Response Pipelines Regulated by AER Questions Before Signing a Pipeline Agreement Oil Batteries and Gas Compressor Plants Gas Plant Risks and Questions Regarding Other Infrastructure | |

| Environmental Impacts | |

| Abandonment and Reclamation | |

| Compensation, Rights, and Hearings | |

| Appendices | |

Contents

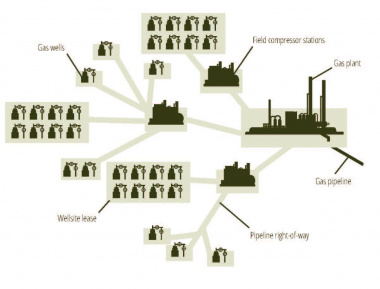

In previous sections, we looked at the issues that arise with the development of new wells and pipelines.[1]

This section will briefly describe batteries, compressor stations, gas processing plants and large production facilities, and outline the regulatory requirements for these facilities. It also provides important questions to ask when a company approaches you to place these facilities on or near your land.

| The AER approval process and many of the issues for batteries, compressors and gas plants are similar to those discussed with respect to wells in Oil and Gas Wells. AER Directive 056: Energy Development Applications and Schedules sets out the requirements that a company must meet, including the consultation or notification of those who may be affected.[2] |

|---|

Batteries, compressors and gas plants go hand in hand with oil and gas wells, and sometimes a company may wish to build these facilities on the wellpad, or nearby as a collection point for other nearby operations. When a company applies for an approval for a facility, they are required to advertise their application and the Alberta Energy Regulator (AER) posts the application on their website. Specific consultation and notification requirements for facilities are noted in Required consultation and notification .

After the application is submitted to the Regulator, you can file a statement of concern to the AER prior to the deadline indicated on the notice of application outlining any concerns you may have with how the project adversely affects you (See When the Application is Filed: Submitting a Statement of Concern and Filing a Statement of Concern for more information about submitting a statement of concern).[3] Additionally, you should send your concerns directly to the company, although they will be notified of a statement of concern. Normally, the company will contact you and seek to resolve your concerns. If the company resolves your concerns by answering your questions or agreeing to a set of actions then you should contact the AER in writing indicating that you no longer have concerns about the project and what commitments the company has made to you. This may help ensure that the AER is aware of, and incorporates, these commitments in advance of approval of the facility. If the AER grants an approval it will set out requirements with respect to air emissions, handling of waste, protection of surface water and groundwater, etc. If you disagree with the Regulator’s decision on an application (if it was made without a hearing), you can appeal the decision. The Regulator has discretion whether it will hear an appeal, and can confirm, vary, suspend, or revoke any of its own decisions.[4]

If you are involved with a proposal to build a compressor, pumping station or gas processing plant you may wish to consult the Alberta Government’s Code of Practice for Compressors and Pumping Stations and Sweet Gas Processing Plants.[5]This sets requirements for air pollution control technology to limit emissions of nitrogen oxides, and for the management of wastewater and runoff.[6]

Oil and Gas Batteries

An oil battery is a facility that collects oil from one or more wells and passes it through equipment to separate out the entrained gas, water and other impurities before piping the oil. There may be flaring from an oil battery and fugitive emissions/odours from the process and tanks. To prevent any oil leaks from spreading, the site will be surrounded by a berm or other containment equipment and surface water will be collected and tested before it is discharged. In some circumstances groundwater may also be monitored.

| Information about possible environmental issues with the operation of batteries is dealt with in Potential Environmental Impacts During Oil and Gas Operations. It will be helpful to review this information if a battery is to be built on or near your land. |

|---|

The AER approval process is similar to that for oil and gas wells, which involves consultation with you as the landowner as well as local residents prior to submitting an application. The procedures a company must follow are set out in AER Directive 056.[7] The AER can impose any conditions it considers appropriate on the licence.

As with wells and pipelines, a company is required to inform you of your rights by providing you with the AER information package (see Public Consultation, Notification and Involvement). The company must also inform adjacent residents of the proposed development and ensure that all parties understand the nature of the development and the equipment that they intend to use.

If people within the vicinity of the facility have any concerns or if they object to the facility, the company is expected to discuss and seek to resolve the issues, using Alternative Dispute Resolution (ADR) mechanisms when needed (see Alternative Dispute Resolution). If the concerns cannot be resolved, the company must make a non-routine application and provide a written summary of the outstanding concerns/objections so the AER can decide whether to issue an approval or conduct a hearing.[8] As the landowner/occupant, it is useful for you to also advise the AER in writing of your concerns. As explained in Signing the Lease Agreement, even if a company has asked for a hearing, negotiations should continue, using appropriate dispute resolution. Since the hearing process can be slow, can delay a project, and are expensive for a company, the company will likely try to resolve your concerns/objections before the hearing date. Public Hearings and Regulatory Board Processes explains the AER hearing process.

| There were over 24,800 oil and crude bitumen and satellite installations in Alberta in 2012 and over 15,700 gas batteries.[9] |

|---|

Compressor Stations

In compressor stations, compressors driven by gas or electric engines apply pressure to gas so that it will flow through process units and pipelines. Compressors come in many different sizes and may be located at a wellhead, battery, or gas plant. Long pipelines may also require a series of compressor stations along the line to boost pressure. A compressor may be heated to prevent freezing and condensation.

More compressors may be required for coalbed methane (CBM) or hydraulically fractured wells than for conventional oil and gas wells. In a CBM development, gas comes to the surface at lower pressure and may require compression close to the wellhead as well as prior to tying into a trunk pipeline. In hydraulic fracturing operations, additional compression is needed to pressurize the fracture fluid to break subsurface rock layers.

You should inquire whether a compressor will be needed on your property, since they can be noisy and are a source of some air pollutants.

The consultation and notification process for compressor stations is similar to that for batteries and the AER requires the company to consult with you as the landowner/occupant as well as nearby residents.[10]

The AER sets standards for acceptable noise levels (see Noise). A number of different compressors are available and some are considerably quieter than others. If a compressor is located close to a dwelling or workplace it is important to discuss noise mitigation measures with the company during your negotiation of a lease to ensure that the best technology is used and your considerations are addressed. If the noise is still disturbing, it may be necessary to use a baffle to further reduce the sound.

There will be combustion emissions (carbon dioxide, nitrogen oxide, etc.) from compressors that are operated by natural gas, while there may be some fugitive emissions from leakages through valves, seals, and other pipe fittings from compressors driven by either gas or electricity. These fugitive emissions can cause or contribute to air quality and/or odour problems, and are further discussed in Air Emissions.

Gas Processing Plants

Gas processing plants remove unwanted substances from the gas before it is transported and sold as marketable natural gas. Some substances are separated out for sale, such as methane, ethane, propane, butane and pentanes. There are also contaminants in the raw gas that much be removed to meet quality specifications, such as water, hydrogen sulphide (H2S), carbon dioxide, nitrogen and other trace gases. There are almost 800 gas processing plants in Alberta.[11]

The AER licensing procedure for gas processing plants is similar to that for other facilities such as batteries. If the company leases a site, they must provide you as the landowner or occupant with the AER information package on public consultation and try to reach agreement with you before applying for a licence. The company must consult with residents within a certain radius of the proposed plant.[12] In the case of sour gas plants, the company will also consult on the emergency planning zone (see Sour Oil and Gas Developments and Emergency Response Plans).

| Members of the public can submit a statement of concern when a company’s application is posted by the Alberta Energy Regulator for a sour gas processing plant (see When the Application is Filed: Submitting a Statement of Concern and Filing a Statement of Concern). |

|---|

Sour gas plants

New sour gas processing plants are required to make a non-routine application to the AER. If members of the public affected by the application have concerns they can file a statement of concern with the AER, as well as contact the company directly.

The AER sets standards to limit the amount of sulphur that can be released from sour gas processing plants. This is expressed in terms of the sulphur recovery required for new plants; the recovery criteria depend on the size of the plant. At sulphur inlet levels below one tonne per day, sulphur recovery is not required. At sulphur inlet rates equal to or greater than one tonne per day, the percentage of sulphur that has to be recovered varies depending on the plant’s inlet rate: those sized at 1 to 5 tonnes per day must recover 70%, while those with inlet rates greater than 2,000 tonnes per day must recover 99.8%.[13] Thus small plants release proportionately more than larger plants.

To prevent the proliferation of plants, a company must “vigorously explore” the possibility of using existing facilities.[14] They must also consult and involve local residents in their evaluation of alternatives. If a company wants to construct a sour gas plant within a 15-km radius of an existing plant, they must show that it is justified in terms of social and environmental effects. The AER has established minimum setback distances for sour gas plants and facilities, are based on the potential release volume of hydrogen sulphide. The minimum setback distances are shown in Table 5. As a landowner, you may want to negotiate a larger setback in certain circumstances.

Table 5. Setback requirements for sour gas facilities

| Level of facility | H2S volume (m3) | Minimum distance |

|---|---|---|

| 1 | <300 | At least 100 m to a lease boundary |

| 2 | 300–2,000 | At least 100 m to individual permanent dwellings and unrestricted country development. At least 500 m to urban centres or public facilities |

| 3 | 2,000–6,000 | At least 100 m to individual permanent dwellings up to 8 dwellings per quarter section At least 500 m to unrestricted country developments At least 1.5 km to urban centres or public facilities |

| 4 | >6,000 | As specified by the AER, but not less than Level 3 |

Source: This table is based on information in AER Directive 056: Energy Development Applications and Schedules, Tables 5.5, 6.3 and 7.5.[15] The reader should refer to these tables for full details.

References

- ↑ This material is from the Pembina Institute publication 'Landowners' Guide to Oil and Gas Development, 3rd edition (2016)'

https://www.pembina.org/pub/landowners - ↑ AER, Directive 056: Energy Development Applications and Schedules (2014), section 5.4 and table 5.1 set out the minimum consultation and notification requirements for facilities. Section 2 of this guide gives the general requirements for participant involvement, with the full process described in Appendix 11. AER Directives are available at AER, “Directives.”

https://www.aer.ca/regulating-development/rules-and-directives/directives.html. This link has been updated since the 2016 publication; the updated link may no longer contain the original information. - ↑ You have the time limit set out in the Notice of Application to submit your statement of concern, which may be less than 30 days.

- ↑ Alberta, Responsible Energy Development Act, SA 2012 c R-17.3, s 42. Alberta government acts and regulations are available at Alberta Queen’s Printer, “Laws Online/Catalogue.”

http://www.qp.alberta.ca/Laws_Online.cfm - ↑ Alberta, Code of Practice for Compressors and Pumping Stations and Sweet Gas Processing Plants; issued under the Substance Release Regulation (AR 124/93).

http://www.qp.alberta.ca/documents/codes/COMPRESS.PDF - ↑ If a facility is not regulated under Alberta’s Environmental Protection and Enhancement Act (RSA 2000, c E-12), it must meet the AER requirements for air emissions.

- ↑ AER, Directive 056, sections 2 and 5.

- ↑ AER, Directive 056, section 3.8.2 and Appendix 11 explain the non-routine application process.

- ↑ Energy Resources Conservation Board, Field Operations Provincial Summary 2012, ST57-2013, 7, 8. http://www.aer.ca/documents/sts/ST57-2013.pdf

- ↑ AER, Directive 056, table 5.1.

- ↑ Field Operations Provincial Summary 2012, 8.

- ↑ AER, Directive 056, table 5.1.

- ↑ AER, Interim Directive ID 2001-03 Sulphur Recovery Guidelines for the Province of Alberta, 2001, 3.

- ↑ Ibid., 15.

- ↑ The AER refers to Category D pipelines (where the pipeline associated with the facility contains gas with more than 10 mol/kmol H2S) and Category C, D or E facilities, which are classified according to the volume of sulphur inlet to the facility. This includes gas processing plants, some gas and oil batteries and straddle plants, etc. Facilities with less than 0.01 mol/kmol H2S in the inlet stream are in Category B and thus exempt. See AER Directive 056, Table 5.1 for full description of categories. The AER provides a H2S Conversion Calculator on their website: https://www.aer.ca/regulating-development/rules-and-directives/directives.html. This link has been updated since the 2016 publication; the updated link may no longer contain the original information.

| ||||||||||||||||||||||||||||||||||||||||||||